In many sectors of the industry, solvents are part of process exhaust gases and must not be released into the environment unfiltered. These volatile components that are contained in exhaust air can have both acute and long-term harmful effects on humans, animals and the environment. Many solvents can cause short-term, but also chronic, carcinogenic, mutagenic and/or reprotoxic effects. This makes it all the more important to have an efficient exhaust air purification system that is specifically designed for solvents.

According to TRGS (Technische Regeln für Gefahrenstoffe; Engl.: Technical Rules for Hazardous Substances) solvents are, in addition to water, primarily volatile organic compounds (VOC) and mixtures thereof with a boiling point of less than 200 °C. They are also liquid at around 20 °C and are used to dissolve or dilute other substances without changing them on a chemical level. Although the solvent itself does not take part in the chemical reaction, it is important for its course.

Various solvents are contained, for example, in cleaning agents, dispersants and preservatives or in plasticisers. They are used, for example, to obtain a certain viscosity or to achieve a desired surface tension of the basic product.

A large number of solvents are critical, as they cause irritations or allergies in humans and animals and represent even more serious health hazards long term. The negative effects of solvents can occur acutely, with a time delay or even manifest themselves chronically.

Solvents are particularly problematic when they not only have an acute, locally restricted effect, but spread through the atmosphere to the entire environment and have long-term consequences for many people. If solvents get into surface water or groundwater, for example, this can pose a serious threat to the drinking water production. Solvents are also partly responsible for the depletion of the ozone layer, which is so vital.

Very often, harmful solvents are contained in varnishes, paints, resins, coatings, or adhesives. For this reason, industries that work with these substances are required to install a reliable exhaust air purification system to remove the harmful solvents from the exhaust air and exhaust gases. The Federal Immission Control Act (German: Bundesimmissionsschutzgesetz BImSchV) and the Technical Instructions on Air Quality Control (TA Luft) specify the maximum values of solvents and other pollutants that may be present in the exhaust air when released into the environment as clean air.

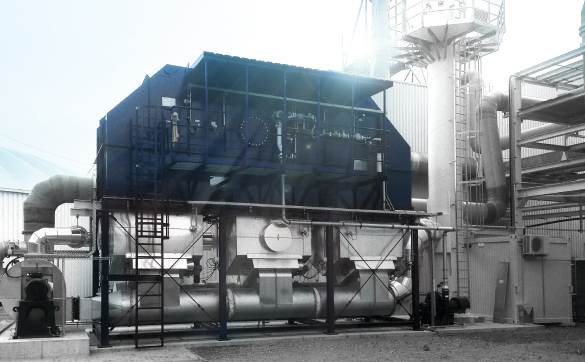

Depending on the concentration and water solubility of the VOC, and taking into account all economic advantages, the solvent filter systems from Wessel-Umwelttechnik clean the exhaust air using biological, absorptive, adsorptive or thermal methods.

Wessel offers plant systems made of different materials such as stainless steels or plastics – depending on the planned application. The systems are tailored to each situation on site. As a manufacturer, we therefore offer exhaust air purification systems that are modularly constructed exactly as required by the conditions on site. Depending on the location and the type of pollutants to be separated in the exhaust air, the various technologies and systems can be combined.

Biological processes such as our BIOCAT Bio scrubber and BIOCAT Biofilter are suitable for removing a range of solvents from the exhaust air. The prerequisite for this, however, is that the solvents are bioavailable. In both, exhaust air purification systems, microorganisms and biocatalysts play a central role. These break down the solvents contained in the exhaust gas into natural, harmless products, but also separate other pollutants and odours.

Thermal cleaning in post-combustion plants is the right choice when neither biological nor absorptive/adsorptive processes are efficient. Combustible volatile organic solvents, usually in the scale of grams, are optimally separated by thermal treatment in such plants.

Gas scrubbers such as the DCS scrubber (Direct Chemical Sorption) are used in the context of chemical-absorptive exhaust air purification. DCS scrubber technology has very high efficiencies of over 90 % in the separation of solvents and VOCs as well as dusts and many other pollutants.

Adsorption systems are also an efficient way of filtering volatile solvents from exhaust air, smoke and waste gases. In contrast to chemical absorption processes, in which harmful substances are bound by the use of liquids, the solvents are physically separated in an adsorption plant. This means: the harmful substances are attached to an adsorbent such as zeolite or activated carbon and thus separated.